Automotive solutions from Berghof Automation

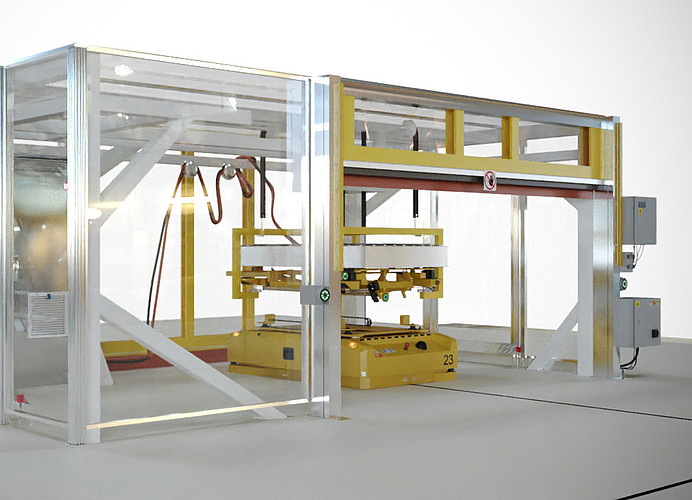

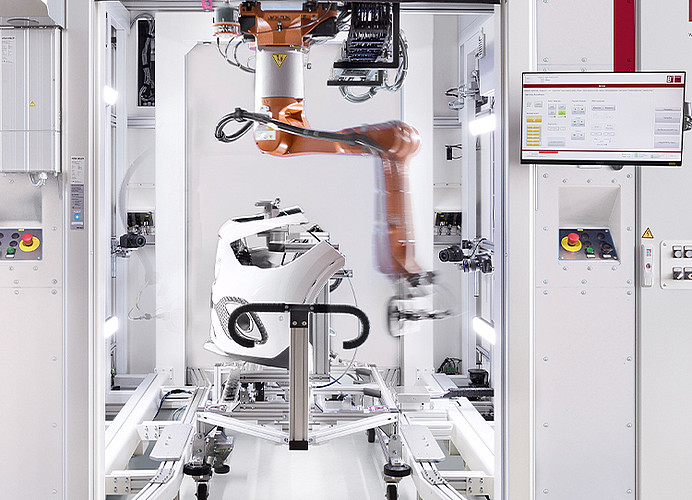

As numerous as the suppliers of vehicle components in the automotive industry are, their requirements for testing systems for their products are equally diverse. Berghof Automation offers modular, intelligent solutions for energy storage testing in both the low-voltage and high-voltage areas. In addition, we are the ideal partner for safety and quality in the interior and exterior area.